WARNING: This product can expose you to chemicals including Cadmium, which is known to the State of California to cause cancer, birth defects or other reproductive harm. For more information go to STEEL PRODUCTS WARNING: This product can expose you to chemicals including Diisononyl phthalate (DINP), which is known to the State of California to cause cancer, birth defects or other reproductive harm. For more information go to SYNTHETIC SUEDE PRODUCTS WARNING: This product can expose you to chemicals including Silica, which is known to the State of California to cause cancer. For more information go to NEOPRENE FOAM PRODUCTS WARNING: This product can expose you to chemicals including Diisononyl phthalate (DINP), which is known to the State of California to cause cancer, and Di-n-butyl phthalate (DBP), which is known to the State of California to cause birth defects or other reproductive harm. See below for the particular warning that applies to you: This is our Proposition 65 warning for vinyl coated products, neoprene foam products, synthetic suede products, steel products, wood products and blue packing tarp used to package and ship our products.

Citizens of other states who purchase goods made or sold by companies doing business in California also encounter these notices and may find them confusing or troubling. Patching: As the foam begins to cure, the holes are patched completely so you'll never know the work was done.PLEASE TAKE TIME TO READ THIS DOCUMENT COMPLETELY.Ĭalifornia residents are generally familiar with California Proposition 65 warnings because they see them so frequently.Clean-Up: The small tails that back up out of the installation holes area cleaned up to leave a smooth wall surface.Filling: Certified installer pumps foam until it begins to appear at the adjacent holes.

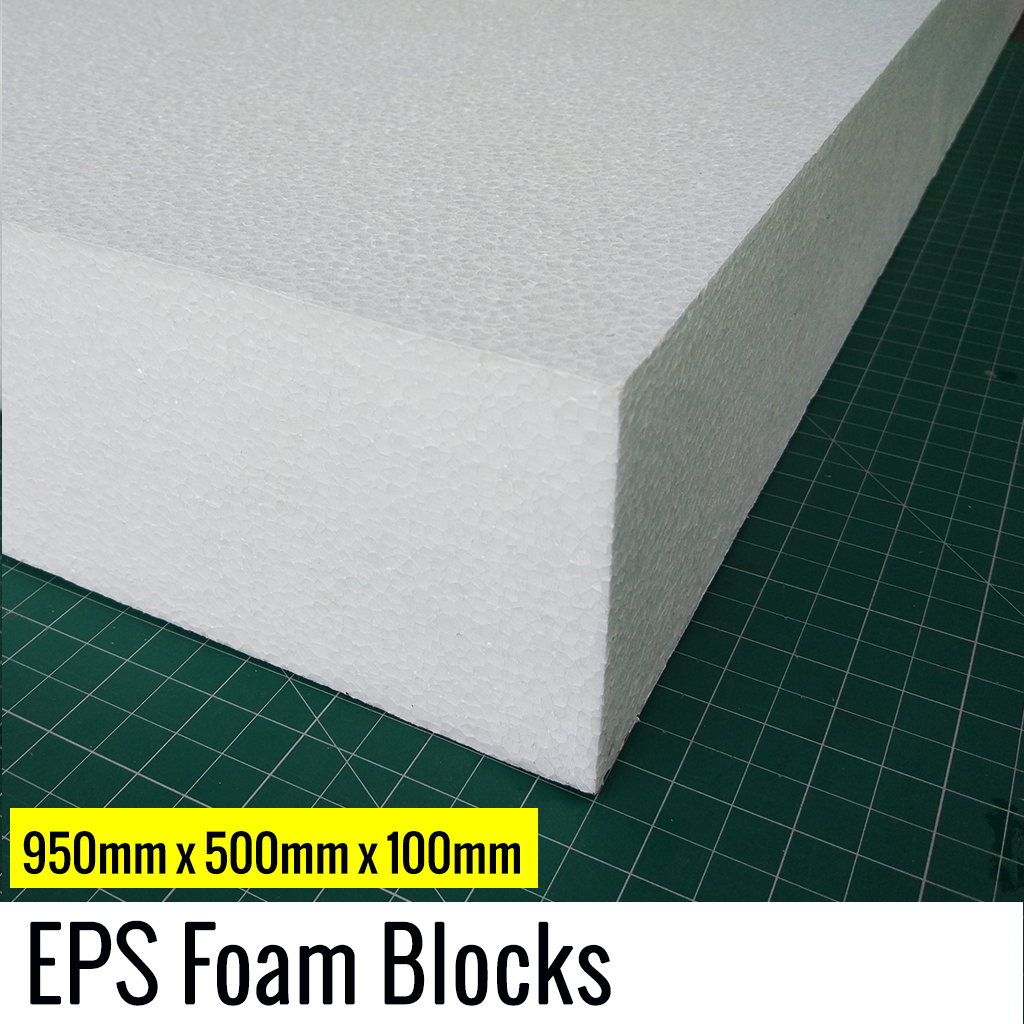

On-Site Quality Control: An experience technician will check the texture, weight and density of the foam to ensure performance prior to and during installation.Drilling: Once the pattern is determined, we'll carefully drill holes in the appropriate locations to ensure proper foam flow during installation.Planning & Prep: We'll carefully examine the structure to be insulated prior to the project.has an easy 6 step process to getting your block foam job completed efficiently and properly: Block foam does not settle and will not be hung up on obstacles such as plumbing, electrical or masonry.īecause of its high efficiency and low cost installation, the block foam process can pay for itself quickly. The pressurized foam spray ensures that the block foam completely fills all crevices and voids that may be inside the wall. will use pressure to pump foam into your walls after cutting a small incision in the wall. Block foam insulation is one of the best insulating materials available due it its ease of installation, superior performance and cost effectiveness.

0 kommentar(er)

0 kommentar(er)